Oilfield customers specify a particular cell for their battery

pack/modules after considering cell characteristics: Chemistry

- Lithium vs. Alkaline Lithium Lithium batteries are very attractive

to the oil industry due to a combination of high energy density, high voltage, high current capability, wide temperature range,

long shelf life, and stable operating voltage. Lithium Thionyl Chloride and Lithium Sulfuryl Chloride cells are also

known as liquid cathode lithium cells. All lithium cells and batteries made with cells larger

than an AA size are restricted to being transported on Cargo Aircraft Only. An exception to this is when a cell manufacturer

performs testing certifying that the cell is non-dangerous as per United Nations guidelines. Although

there are many variations of lithium cells, the following 3 types are most commonly used in the oil patch.

Lithium

Thionyl Chloride (Li/SOCL2) Probably the most commonly used type, lithium/thionyl

chloride cells have one the highest energy densities of available battery systems. All of our suppliers manufacture

this type, and a variation of this system is available with maximum temperature ratings of 180oC and 200oC. | Lithium Thionyl Chloride | | | Open Circuit Voltage | 3.67 V | | Nominal

Voltage | 3.4 V | | Discharge Profile | Flat | | Available Temp. Rating | 85°C, 150oC, 180oC and 200oC |

Lithium Sulfuryl Chloride (Li/SO2CL2) Although

similar, this type is different from Lithium/Thionyl Chloride cells in the following ways: - higher energy density due to higher voltage

- increased current

capability due to higher conductivity of electrodes

A variation

of this system is available with a maximum temperature rating of 165oC.

| Lithium/Sulfuryl Chloride | | | Open Circuit Voltage | 3.9 V | | Nominal Voltage | 3.5 V | | Discharge

Profile | Flat | | Max. Avail. Temp. Rating | 150oC

and 165oC |

Alkaline

(Zn/alkaline/MnO2) Because of its low maximum temperature rating

(93oC), alkaline cells have limited use in the oil patch. However, in cooler applications, alkaline cells

are an excellent choice due to their low cost, high power output, safety, and no restrictions in transportation. | Alkaline | | | Open Circuit Voltage | 1.5 V | | Nominal Voltage | 1.2

V | | Discharge Profile | Sloping | | Max. Avail. Temp. Rating | 93oC |

Energy Density Comparison

A comparison of Energy Density for different primary battery chemistries. This is an approximation

due to manufacturer's differences in the methods used to collect this data

Current Capability

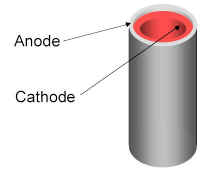

All of the lithium cell manufacturers utilize 3 basic types of construction: Bobbin, Moderate Rate,

and Spiral. The cell construction determines the amount of common surface area between the anode (lithium) and the cathode

(high surface area carbon cathode). The amount of electrode surface area is proportional to the current capability of

the cell. Bobbin This type has a small common surface area between the anode and the cathode. Basically

it consists of one cylinder of cathode surrounded by one cylinder of anode material. The low common surface area results

in low rate discharge capability. The advantages of this type of cell are its low manufacturing cost, low self discharge

rate, and no safety fuse requirement. These cells' limited current capability and the resulting effect of

passivation may limit their use in high current applications.

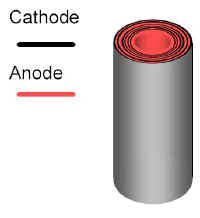

Moderate Rate Similar to the Bobbin style, the moderate rate, otherwise known as dual or double

anode, incorporates another layer of anode material in the center of the cathode. Although manufacturers' assembly

techniques vary, the goal with this type of construction is to increase the common surface area between the electrodes so

that the cell has a higher current capability than a bobbin cell. Like a bobbin cell, this type does not generally need

a safety fuse.

Spiral Also

known as jelly roll construction, spiral cells have a very large common surface area  between the anode and the cathode; thus the current capability of these cells is very high. Although high rate cells

require safety fuses, they are able to produce enough current to satisfy most downhole tool requirements without the effects

of passivation. between the anode and the cathode; thus the current capability of these cells is very high. Although high rate cells

require safety fuses, they are able to produce enough current to satisfy most downhole tool requirements without the effects

of passivation. * VERY IMPORTANT * Some spiral cells are case positive and some are case negative. Caution is required when wiring

into a series string not to mix polarity.

Temperature Rating

Manufacturers use various methods to design a cell chemistry in order to operate at a particular maximum temperature.

It is recommended that users specify the lowest temperature rated cell that can be safely used. This is because

higher temperature cells tend to be more expensive, and they have some performance drawbacks if the cells are used at low

temperatures.

Under no circumstances should a user attempt to use a cell in an environment exceeding the temperature

rating of the cell.

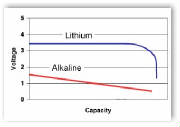

Voltage

Keep in mind that the operating voltage is lower than open circuit voltage. Lithium cells, depending

on the load and chemistry, have an operating voltage ranging from 2.5 - 3.9 volts. Alkaline cells operate between 0.8

- 1.6 volts. While alkaline cells' voltage decreases over the length of discharge,

lithium cells maintain a steady voltage until near the end of discharge.

Assembling

cells in series: the voltage multiplies by the number of cells.

Assembling

cells in parallel: the current capability and capacity multiplies by the number of cells in parallel.

| Chemistry | Voltage | | Lithium/Thionyl Chloride | 3.6

V | | Lithium/Sulfuryl Chloride | 3.9 V | | Alkaline | 1.5 V |

Resistance to Shock and Vibration

Spectrum Batteries has cells available in all sizes that are capable of withstanding

the high shock and vibration typically encountered in downhole drilling conditions. For more information on

the proper cell selection for applications in these harsh environments, please contact us at info@spectrumbatteries.com.

Dimensions

Cells available

from Spectrum Batteries are optimally sized for downhole tools. Our cell suppliers have developed special sized

C, CC, and DD cells to fit in these demanding applications. The Spectrum Batteries alkaline cell is slightly smaller

than most commercially available alkaline cells making it optimally sized for bottom hole pressure surveys

|